As rapidly deployable building units, inhabited containers are subject to stringent standard requirements in design, manufacturing, and usage. This article outlines key standards from four dimensions—structure, fire safety, safety, and environmental protection—for your reference in procurement and inspection.

Structural Design

Strength Requirements: Containers must withstand specified stacking loads and dynamic loads. A common requirement is to endure a pressure equivalent to 1.8 times the maximum stacking weight during a stacking test for 24 hours without permanent deformation or failure.

Stiffness Control: Under load, the deformation of the entire structure and critical components (e.g., corner fittings) must remain within allowable limits to ensure stability during multi-layer stacking and lifting.

Connection Quality: Welding or bolted connections between corner fittings, beams, panels, and the container body must meet weld size and mechanical performance requirements. The tensile strength of welds should generally be no less than 85% of the base material to prevent connection failures that could lead to safety incidents.

Fire Safety Standards

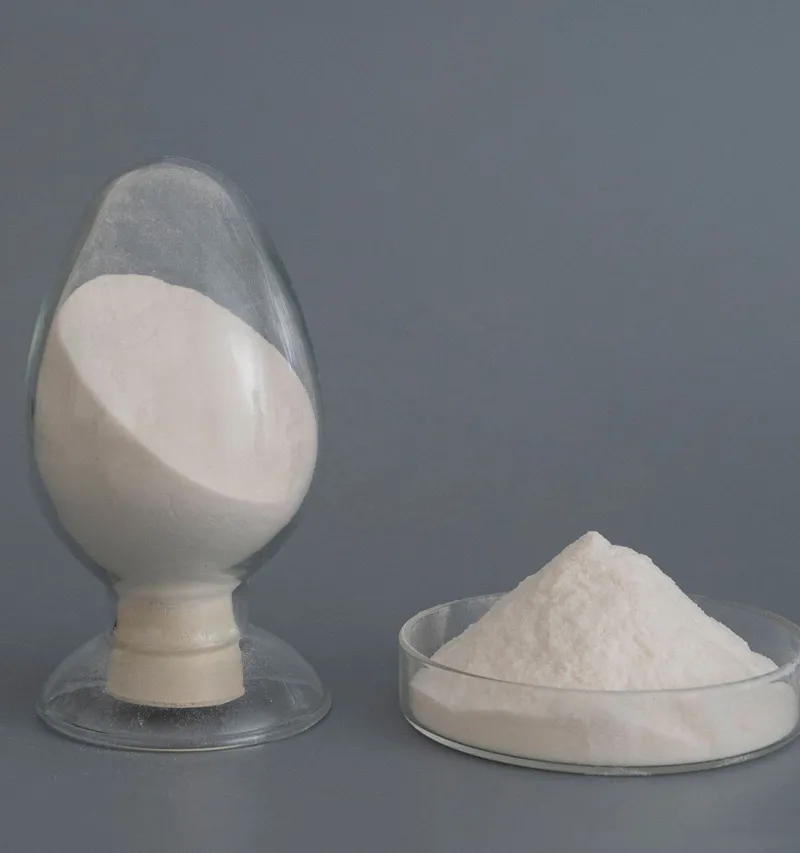

Walls and roofs should be constructed from non-combustible or flame-retardant materials, with a fire performance rating of Class A or at least Class B1. Rock wool sandwich panels, known for their low thermal conductivity and excellent fire resistance, are commonly used to effectively delay fire spread. For large interior spaces, fire compartments should be designed, with firewalls and other components having a fire resistance rating of no less than 3 hours to ensure sufficient time for evacuation and rescue.

Safety Requirements

Ventilation: Must comply with residential health standards. The ventilation opening area for each living unit should not be less than 5% of the floor area, with at least half of it operable to ensure adequate airflow and removal of harmful gases.

Door and Window Dimensions and Safety: Door clear width should be no less than 0.9 meters, and height no less than 2.0 meters. Windows should balance natural lighting and safety, with double-layer tempered safety glass preferred due to its significantly higher impact resistance compared to ordinary glass.

Electrical Systems: Wiring and distribution equipment must comply with national electrical codes. Cable specifications and rated voltage should meet load requirements. Distribution boxes must be equipped with leakage protection devices, with a trip current no greater than 30 mA and a trip time not exceeding 0.1 seconds to reduce the risk of electric shock and electrical fires.

Environmental Protection and Comfort

Materials must meet harmful substance standards, particularly for artificial panels, where formaldehyde emissions should achieve E1 grade to avoid long-term health hazards. Sound insulation is also crucial for living quality. Walls and roofs should provide a sound insulation level of at least 30 dB(A) to ensure a quiet living environment, especially in camp or temporary housing scenarios.

Inspection and Implementation Recommendations

During procurement, request test reports and material qualification certificates from manufacturers. During on-site installation, pay attention to weld quality re-inspection, grounding and electrical system coordination, and thorough checks of ventilation and waterproofing details. For customized projects, clarify load requirements, floor height, fire compartments, and mechanical-electrical interfaces during the design phase to avoid rework later.

As a professional manufacturer of inhabited containers, our company not only meets the above standards but also emphasizes traceability in production and delivery, as well as engineering coordination capabilities. For clients, the most important aspect is to clearly specify key technical indicators, inspection methods, and responsibility allocation in bidding documents and contracts to ensure project safety, reliability, and timely delivery. Please feel free to contact us for more details.