Magnesium Oxide (MgO) board is a versatile building panel made from magnesium oxide, derived from seawater. It acts as a superior alternative to traditional drywall or cement board, offering exceptional fire resistance, mold resistance, durability, and environmental sustainability for modern construction.

This isn't just another drywall alternative. MgO board represents a fundamental shift in how we think about wall and ceiling systems. Let's explore what makes it different.

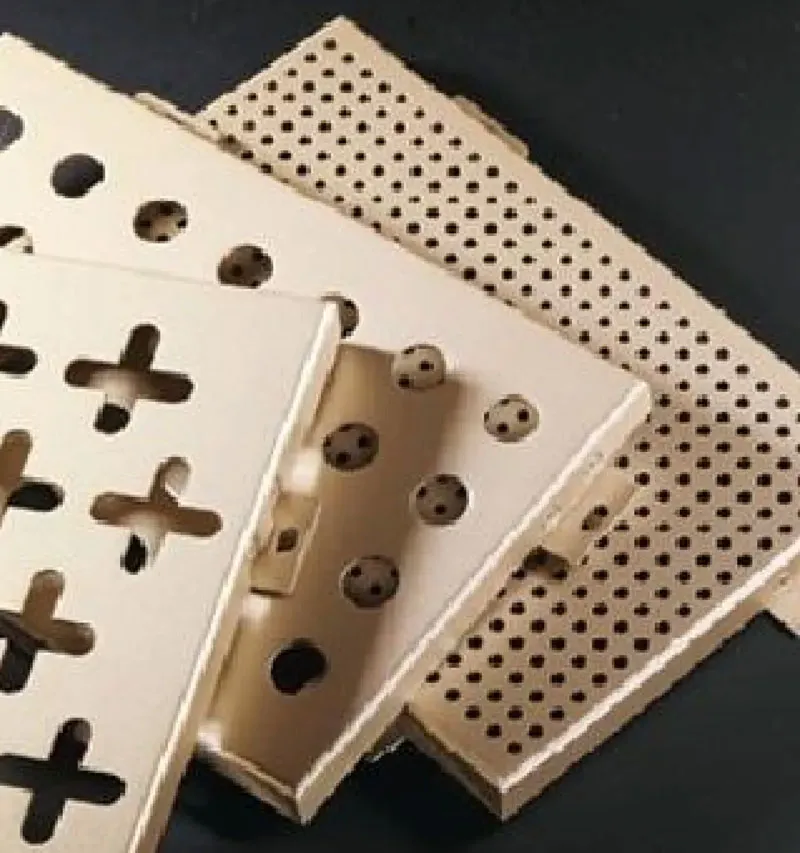

How Are MGO Boards Manufactured?

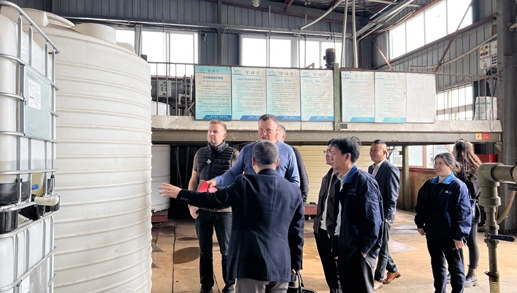

I visited a manufacturing plant and was struck by the clean, precise process. It felt more like a tech assembly line than a traditional building materials factory.

MgO boards are created through a mixing and pressing process. Magnesium oxide, extracted from magnesium salts in seawater, is combined with magnesium chloride and reinforced with fiberglass mesh. This mixture is then pressed into sheets and cured, resulting in a dense, stable, and incredibly strong panel.

The manufacturing magic lies in the chemical reaction that occurs, creating a stone-like matrix that gives the board its unique properties.

The Science Behind the Sheet

The production of MgO board is a carefully controlled chemical process. It starts with sourcing raw materials, primarily from seawater, making it an abundant and sustainable resource. The magnesium oxide powder is mixed with a magnesium chloride solution, which acts as a binder. This slurry is then layered with fiberglass mesh for tensile strength, much like rebar in concrete.

The layered material passes through rollers that press it to a precise thickness. This compression is crucial for achieving the board's density and uniformity. Finally, the boards are cured. During curing, a chemical reaction called Sorel cementation occurs, forming a hard, stable magnesium oxychloride cement. This process does not require high-temperature kilns like gypsum board, which contributes to its lower carbon footprint. The result is a panel that is dimensionally stable, meaning it expands and contracts very little with changes in temperature and humidity, preventing the cracks and seams that often plague drywall.

MgO vs. Cement Board: Which Performs Better?

On a high-humidity project, we used cement board in one bathroom and MgO in another. The difference in handling and long-term performance was undeniable.

MgO board is generally lighter, easier to cut, and more resistant to mold and fire than standard cement board. While cement board is very durable and waterproof, MgO board offers a wider range of benefits, including better thermal insulation and a more environmentally friendly profile.

Choosing between them isn't just about durability; it's about matching the right material to the project's specific needs.

A Detailed Comparison for Builders and Homeowners

While both materials are used in wet and demanding applications, their performance characteristics differ significantly. Cement board is a workhorse, known for its compressive strength and excellent waterproofing, making it a default choice for tile underlayment in showers. However, it is heavy, difficult to cut without specialized tools, and creates a lot of silica dust, which is a health hazard.

MgO board, in contrast, is significantly lighter, which makes installation faster and less labor-intensive. It can be scored and snapped like drywall, though using a saw is cleaner. Its inherent resistance to mold is a key advantage. While cement board doesn't promote mold growth itself, it doesn't actively resist it like MgO does. From a health perspective, MgO board is non-toxic and produces no harmful silica dust when cut. In terms of fire performance, MgO board is incombustible and can achieve higher fire-resistance ratings than many cement boards. Its thermal insulation properties are also better, which can contribute to improved energy efficiency in a building.

| Feature | Magnesium Oxide (MgO) Board | Cement Board |

| Weight | Lighter, easier to handle | Heavy and dense |

| Workability | Easier to cut and shape | Difficult to cut, produces silica dust |

| Mold Resistance | Inherently mold-proof | Mold-resistant but not proof |

| Fire Resistance | Incombustible, high fire rating | Non-combustible, high fire rating |

| Environmental Impact | Made from abundant, often recycled materials; low-energy production | Energy-intensive production process |

| Best Use Cases | Interior walls, ceilings, soffits, sheathing | Shower/tub surrounds, exterior sheathing |

Where Can Magnesium Boards Be Used?

I've specified MgO board for everything from a high-end kitchen backsplash to a basement renovation. Its versatility consistently impresses clients and contractors alike.MgO board is suitable for a vast range of interior and exterior applications. Common uses include interior wall and ceiling linings, bathroom and kitchen tile underlayment, exterior sheathing, soffits, and as a fire-rated barrier in multi-family and commercial construction.

Its ability to perform in high-moisture and high-risk areas makes it a true all-in-one solution for modern building envelopes.

Unlocking the Full Potential of MgO Applications

The use cases for MgO board extend far beyond a simple drywall replacement. Its combination of properties allows architects and builders to simplify material selection. For interior walls, it provides a durable, vapor-permeable surface that helps regulate indoor humidity, reducing the risk of condensation and mold growth in wall cavities. This makes it ideal for basements, bathrooms, and kitchens.

As exterior sheathing, it creates a strong, fire-resistant, and weather-resistant barrier. When used in soffits and other exterior trim, it holds up against the elements without rotting or warping. In commercial settings, its fire-resistant properties are paramount for creating fire-rated assemblies in stairwells, elevator shafts, and corridor walls. I've even seen it used successfully as a substrate for thin brick and stone veneers, where its flat, stable surface is a major advantage. For DIY enthusiasts, its ease of use makes complex projects like building custom shower niches or durable workshop walls more accessible. The key is to ensure it is detailed and finished correctly, particularly for exterior applications where proper flashing and sealing are required.

Magnesium Oxide board is a durable, versatile, and sustainable building material that outperforms traditional options in fire safety, mold resistance, and overall resilience.